KiTEC Composite Piping System

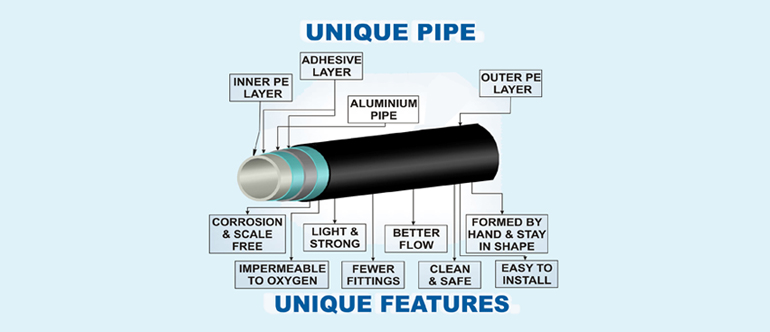

KiTEC is an aluminium and polyethylene composite that combines the best features of both materials to form a pipe that is light, strong and does not support corrosion. By combining the two materials, KiTEC pipe avoids the unaccepted thermal expansion and deformation of plastic pipe. At the same time it retains the flexibility, frost resistance and ease of use associated with plastic. Functional properties of various layers are as follows :

Plastic (PE) Layers :

- PE layers of composite pipe provide all the advantages of plastic pipes such as,

- Corrosion resistance

- Chemically inert

- Smooth surface for better flow properties.

Tie Layers :

- The tie layers have the following functions :

- To perfectly bond the metal and plastic.

- Absorb eventual shifting movements between plastic & metal, likely to occur in opposite directions.

- To give the Composite pipe the advantages of a single component pipe.

Aluminium (Metal) Layer :

- In addition to all the inherent advantages of plastic pipes the inclusion of the metallic pipe gives Composite pipe the qualities of metal, namely : Absolute tightness

- Mechanical resistance to deformation

- Dilation within reasonable limits.

KiTEC Composite Pipes conform to IS : 15450-2004 "Standard Specification for Polyethylene/ Aluminium/ Polyethylene (PE-AL-PE) Composite Pressure Pipe."

KiTEC Composite Pipes are having pressure rating of 13.8 Kg/Cm2 at 23oC. and 11.0 Kg/Cm2 at 60oC. KiTEC Composite piping system can safely be used for 6 Kg/Cm2 pressure at 80oC working temperature. Short term excursions to 95oC. will not affect the overall performance. Design life span for KiTEC Composite Piping System is in excess of 50 years.

Application

- Plumbing - Hot & cold

- Air Conditioning

- Solar Heating

- Submersible Pump Piping

- Jet Pump Piping

- Refrigerant Systems

- Radiator Central Heating

- Under Floor Heating

- For Diesel / petrol / Kerosene

- Fuel Oil Lines

- Cable Conduits

- Compressed Air Systems

- Natural Gas Distribution

- Food / Chemical Processing

- Vacuum Systems

- Insecticides Spraying